What is cable tension clamp?

Cable tension clamp is hardware fittings used to secure optical cable, withstand the tension of the cables, and hang the cables onto utility poles or towers. They play an anchoring role at locations such as corners, tension points, and terminal towers in optical cable lines, ensuring the safe operation of the cables under various environmental conditions. Different types of cable tension clamp is made from different materials and have varying sizes. Common materials used for cable tension clamp includes aluminum alloy, steel, and plastic. These clamps are reliable and durable, significantly enhancing the cables’ tensile and anti-sagging capabilities under complex conditions, thereby ensuring the stability and safety of the cables.

What is the type of cable tension clamp?

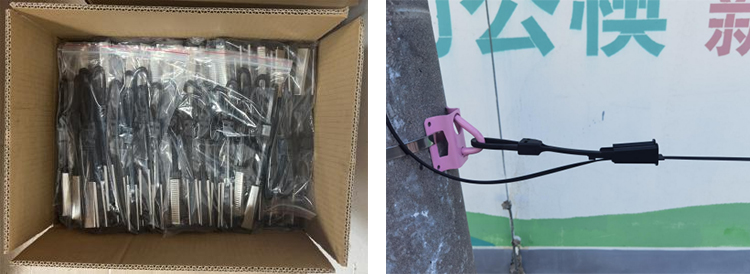

Polyamide wire cable tension clamp

The polyamide wire cable tension clamp is a type of plastic cable clamp, crafted from high-quality UV-resistant thermoplastic material using injection molding technology. It is widely used to support telephone cables or butterfly introduction optical cables in applications such as span clamps, drive hooks, and various drop attachments. The wire cable tension clamp consists of three main parts: a shell, a shim, and a wedge. The insulated drop wire clamp effectively reduces the working load on the support wire. It is known for its excellent corrosion resistance, good insulating properties, and long service life.

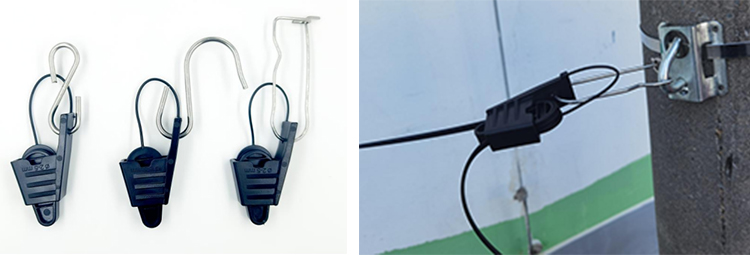

S Hook Cable Tension Clamp

This cable tension clamp consists of two parts: a stainless steel draw hook and reinforced nylon. The open wire hook provides universal fixation on closed hook mounts during aerial fiber optic cable installation. The hook is designed as a non-drop-off part. The drop wire clamp features a self-adjusting wedge that prevents cable damage. It is suitable for small circular optical cables and butterfly optical cables, with the wedge-shaped design fully meeting the requirements of the minimum bending radius of optical fibers.

Wire Cable Tension Clamp

The wire cable tension clamp consists of two main components: a retractor made from stainless steel (grade 201 or 304) and a body crafted from reinforced nylon. The product is primarily designed for use with FTTH butterfly cables and features exceptional tensile strength, as well as outstanding corrosion resistance, heat resistance, and toughness. During the production of the nylon component, the factory customizes the material formula based on the specific tension requirements provided by customers. This allows the clamp to achieve tension capabilities ranging from 0.5 to 1.5 kN, meeting a variety of needs.

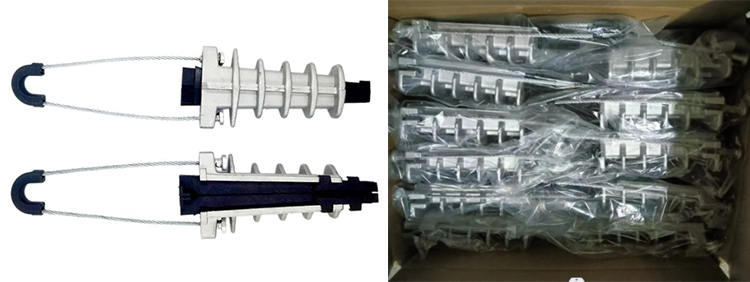

High Tension Cable Clamp

The high tension cable clamp is a robust tensile cable clamp designed for wire diameters of 8-11mm, 10-14mm, and 12-16mm. Unlike ordinary plastic materials, it features a super-strong aluminum alloy shell that is integrally formed to provide stable tensile grip support. The interior is equipped with a strong nylon wedge for secure cable fixation. Customers can choose 4.0mm high-strength, galvanized carbon steel wire. This high tension cable clamp is widely used in various ADSS-type optical cables and composite round wire cables.

J hook Cable Tension Clamp

This cable tension clamp consists of a TPR plastic insert and a galvanized steel shell. The special wire clamping method, utilizing soft rubber, ensures that the cable is held securely and safely. It is designed to suspend ADSS round optical fiber cables during the construction of transmission lines, clamping the optical cable without causing any damage. A wide range of gripping capacities and mechanical resistance is achieved through a diverse product range, featuring different sizes of neoprene inserts. The metal hook of the suspension clamp allows for installation on poles using a stainless steel band and pigtail hook or brackets. Additionally, the hook of the ADSS clamp can be produced from stainless steel materials according to your request.

Suspension Span Cable Tension Clamp

The suspension span cable tension clamp features high-carbon steel bent hooks and aluminum base pressure blocks. The aluminum blocks are secured to the overhead steel strand using screws, with matching upper and lower pressure blocks. This product is designed for overhead cables that need to be pulled down and suspended using cable clamps. It is stable and durable. The surface of the carbon steel hook is cold galvanized, and the main body is made from aluminum alloy material. This ensures stability, protects the product in the field environment, extends its service life, and enhances its aesthetic appeal.

How to choose cable tension clamp?

When selecting cable tension clamps, the key considerations are the cable type, parameters, and installation environment.

For cable type and parameters, the structure, outer diameter, weight, and sheath material are crucial. Different cable structures need different clamps. For example, armored cables need stronger clamps, while loose-tube fibers need flexible ones. The outer diameter and maximum allowable tension of the cable are key parameters. The clamp’s rated load must be equal to or greater than the cable’s maximum tension to prevent slippage or damage. The sheath material also affects the clamp design. Common materials like PVC, LSZH, and PE have different friction and temperature resistance. Depending on the material, anti-slip liners may be needed to prevent slippage and protect the sheath.

When considering installation environment, temperature range, humidity, salt fog, chemical corrosion, and UV exposure are important factors. For extreme temperatures, materials like stainless steel or special engineering plastics are preferred. For corrosive environments, stainless steel (e.g., 316L) or galvanized steel-coated clamps are better. For UV exposure, materials like nylon or modified polymers are recommended.

To select the right cable tension clamp, consult the manufacturer with the cable specifications and environmental parameters. Conduct small-scale tests before bulk purchasing to verify the clamping effect and durability. This ensures the clamp meets mechanical requirements and adapts to the application environment, guaranteeing long-term stable operation of the cable system.