How to distinguish between fiber optic patch cords and pigtails

In fiber optic communication systems, fiber patch cords and fiber pigtails are two common fiber optic components. Although they look similar, their structures, uses, and installation methods are significantly different. Correctly distinguishing between the two is crucial for the deployment, maintenance, and troubleshooting of fiber optic networks. This article will compare the characteristics of jumper fibers and pigtail fibers in detail to help readers quickly identify and reasonably select these two key fiber optic connectors.

1. What are fiber pigtails and fiber jumpers?

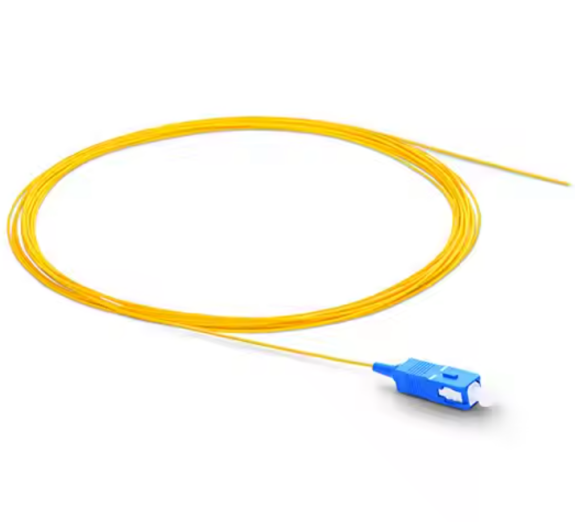

1.1 Complete technical definition of fiber pigtail

Fiber pigtail is a professional optical communication component, and its technical characteristics include:

Structural composition: It consists of three parts – connector end (including ceramic ferrule), buffer fiber segment (0.9mm/3mm), bare fiber end (250μm coating).

Material characteristics:

Connector material: metal (FC type), plastic (LC type) or composite material.

Ferrule material: zirconia ceramic (conventional) or metal (special application).

Fiber type: G.652.D (single mode), OM3/OM4 (multimode).

Optical performance:

Typical insertion loss: ≤0.2dB (including connector).

End face curvature radius: 10-25mm (UPC type).

Fiber eccentricity: ≤0.5μm (high quality product).

1.2 Detailed explanation of the technical specifications of fiber optic jumpers

The complete technical features of fiber optic jumpers include:

Structural design:

Dual connector structure (can be asymmetric).

Reinforcement member: aramid yarn or metal wire (tensile strength ≥100N).

Sheath material: PVC/LSZH/TPU, etc. (different flame retardant levels).

Transmission performance:

Bandwidth characteristics: multimode @850nm (OM4 ≥4700MHz·km).

Polarization characteristics: single-mode jumper PMD ≤0.1ps/√km.

Temperature characteristics: -40℃~+75℃ (industrial grade).

Mechanical properties:

Bending life: ≥5000 times (radius 30mm).

Torsion performance: ±90° (100 cycles).

Flattening test: 1000N/5min (sheath does not deform).

2. How to distinguish the physical structure and appearance details of fiber pigtails and fiber optic jumpers?

2.1 In-depth comparison of connector systems

Features of fiber pigtail connectors:

Internal structure:

Flange diameter: 1.25mm (LC), 2.5mm (SC/FC)

Centering mechanism: precision ceramic sleeve

Locking method: push-pull (LC), threaded (FC)

End surface treatment:

Grinding process: three types of PC/UPC/APC

Surface roughness: Ra≤20nm (high-quality product)

Vertex offset: ≤50μm (compliant with IEC standards)

Features of fiber jumper connectors:

Combination form:

Homogeneous connectors: LC-LC, SC-SC, etc.

Heterogeneous connectors: LC-SC, FC-ST, etc.

High-density combination: MPO/MTP type (12/24 cores)

Special design:

Dustproof type: with self-closing shutter

Reinforced type: metal shell + anti-bending protection

Intelligent type: with electronic identification (NFC tag)

2.2 Engineering-level comparison of line structure

Features of fiber pigtail line:

Bare fiber processing:

Coating stripping: retain 250μm bare fiber

End face preparation: 8° angle cutting (APC type)

Protection measures: fusion protection sleeve (60mm long)

Mechanical properties:

Tensile strength: 5-10N (short term)

Minimum bending radius: dynamic 30mm/static 15mm

Torsion angle: ±45° (during installation)

Features of fiber jumper line:

Cable core structure:

Center reinforcement: FRP/steel wire (diameter 0.5-1mm)

Buffer layer design: tight sleeve/loose sleeve structure

Sheath thickness: 0.5-1.0mm (different materials)

Environmental adaptability:

Waterproof grade: IP67 (outdoor type)

UV resistance: 2000 hours aging test

Flame retardant grade: IEC60332-1/3

2.3 Professional interpretation of product identification and packaging

Fiber pigtail identification system:

Label content:

Product model: PT-SC/UPC-1M (example)

Fiber type: SMF-28e/OM4

Serial number: traceable independent code

Packing specifications:

Standard packaging: 12 pieces/bag (anti-static packaging)

Protective measures: double-ended dust caps

Storage conditions: temperature 15-30℃, humidity <70%

Fiber jumper identification system:

Label information:

Complete model: PC-LC/SC-3M-OM4

Performance level: Cat6a/IEC61753-1

Certification mark: UL/CE/RoHS

Packaging features:

Independent packaging: anti-static bag + hard jacket

Accessory configuration: cleaning card + instructions for use

Transport packaging: shockproof carton (50 pieces/box)

3. What are the application scenarios and technical parameters of fiber pigtails and fiber jumpers?

3.1 Engineering application details of fiber pigtails

Telecom network applications:

OLT terminals:

Requirements: APC end face (RL ≥ 60dB)

Configuration: 1×32 splitter + pigtail bundle

Splicing loss: ≤0.05dB (G.657.A2 optical fiber)

Base station connection:

Special requirements: anti-vibration design

Typical configuration: FC/APC pigtail (3m)

Environmental adaptability: -40℃~+85℃

Data center applications:

Cabbing system:

High-density configuration: MPO-12-core pigtail

Polarity management: A/B/C three polarities

Loss budget: ≤0.5dB/connection point

Equipment interconnection:

40G/100G applications: OM4 multimode pigtail

Parallel optics: 8-core/12-core pigtail bundle

Bending insensitive: G.657.B3 optical fiber

3.2 Professional application scenarios of fiber optic patch cords

Enterprise network deployment:

Structured cabling:

Trunk patch cord: OM4 multimode (50/125)

Horizontal patch cord: Cat6A+dual-core LC

Management room patch cord: color coding system

Special environment applications:

Clean room: dust-free patch cord

Industrial environment: armored patch cord

Medical application: radiation-resistant patch cord

Test and measurement application:

Certification test:

Reference patch cord: IEC Class I standard

Test adapter: interchangeable interface

Loss stability: ±0.02dB

Laboratory application:

High power patch cord: end-face coating treatment

Polarization-maintaining patch cord: PANDA type optical fiber

Ultra-long distance: OS2 single-mode patch cord

3.3 Comprehensive comparative analysis of technical parameters

Optical performance comparison table:

Parameters Fiber pigtail Fiber optic patch cord

Insertion loss (IL) ≤0.2dB (including connector) ≤0.3dB (dual connector)

Return loss (RL) UPC≥50dB, APC≥65dB UPC≥50dB, APC≥60dB

Bandwidth characteristics Not applicable OM4@850nm:4700MHz·km

Mode field diameter 9.2±0.4μm (single mode) Same as left

Mechanical performance comparison table:

Parameters Fiber pigtail Fiber jumper

Tensile strength Short-term 5N/long-term 1N Short-term 30N/long-term 10N

Bending life 100 times (radius 20mm) 1000 times (radius 30mm)

Plug-in durability 50 times 500-1000 times

Vibration performance 10-55Hz, 1.5mm amplitude Same as left, higher vibration resistance

4. Conclusion:

Through a comprehensive comparative analysis of fiber pigtails and fiber patch cords, we can summarize the following key conclusions:

4.1 The essential difference is clear:

Fiber pigtails are “semi-finished” components designed for permanent fusion installation.

Fiber patch cords are “finished” components used for flexible connection between devices.

This fundamental difference determines their different roles and positions in the network.

4.2 Technical selection basis:

When fusion with optical cables or inside equipment is required, fiber pigtails must be used.

When two device ports need to be quickly connected, fiber patch cords should be selected.

Wrong choice will lead to installation difficulties or system performance degradation.

4.3 Performance index differences:

Fiber pigtails pay more attention to the processing quality and consistency of the fusion surface.

Fiber patch cords pay more attention to connection The durability and transmission stability of the device.

The two have different industry standards for indicators such as insertion loss and return loss.

4.4 Engineering application suggestions:

The component requirements of each node should be clarified during the network deployment planning stage.

It is recommended to retain 10-15% of spare jumpers to cope with temporary adjustments.

The pigtail fusion work must be performed by certified technicians.