V-groove materials and V-groove distinguish of mainstream connectors in Brazilian market

With the development of the FTTH market in Brazil, field assembly connectors are increasingly widely used in fiber-to-the-home construction. In the mainstream of connector use in Brazil, the T-BASE model has always occupied a very important position.

With the market’s sensitivity to price and the drive of profit, plastic V-groove connectors from Chinese suppliers have begun to appear in the Brazilian market. Many distributors or construction personnel are not clear about the difference between these two V-groove structures.

Now we make a comprehensive comparison from the perspective of the production plant in terms of structure and environment.

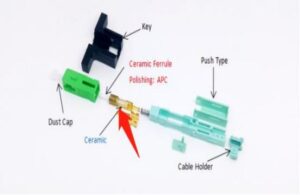

The picture below shows the plastic V-groove products

Different from the ceramic V-groove, the material of the plastic V-groove is basically PEI material, while the structure of the ceramic V-groove is ceramic (positioned by the red arrow).

Because of the inherent characteristics of ceramics, the material stability will be better under the changes of high and low temperature (environment), so the data of the field assembly connector with ceramic V groove will more stable, usually the data change will not exceed 0.3db-0.5dB.

Climate testing

However, due to the limitations of PEI material, plastic V groove has a certain probability of data change under high and low temperature (environment), usually within 1dB; but if the fiber support force inside V groove cannot reach 3N, the impact of high and low temperature (environment) on the data and even affect the connection of the whole network.

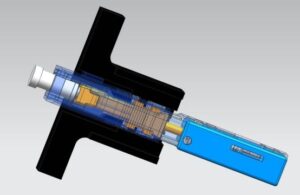

The picture below shows the internal structure of the V groove under a high-power microscope.

The inside of the red frame is the pre-embedded fiber, and the arrow position is the fiber insertion position.

When the temperature changes, the plastic material in the V groove will be affected by thermal expansion and contraction, and will be slightly displaced, which will cause the optical fiber to shift, which will affect the docking and affect the data.

The data changes of the ceramic V-groove and the plastic V-groove under the special environment are analyzed above.

If under normal use, is there any difference between the data of these two products? Our answer is-basically no.

At present, the mainstream connectors in Brazil are mainly plastic V-groove, Sumitomo(click) model, screw model, twist model.

Sumitomo model V-groove structure and materials

Screw model V-groove structure

Twist model V-groove structure

We suggest that if customers do not consider the special structure of the product, the screw type and spiral type are very good products, they are relatively more cost-effective, and the products have undergone sufficient market competition.

But the product quality of different suppliers varies greatly because of the over-competition, as the factory will control the cost through materials and production steps, relatively speaking, it will be more important to choose the right supplier.