Performance of Different Ceramic-V Grooves Under Climate Testing

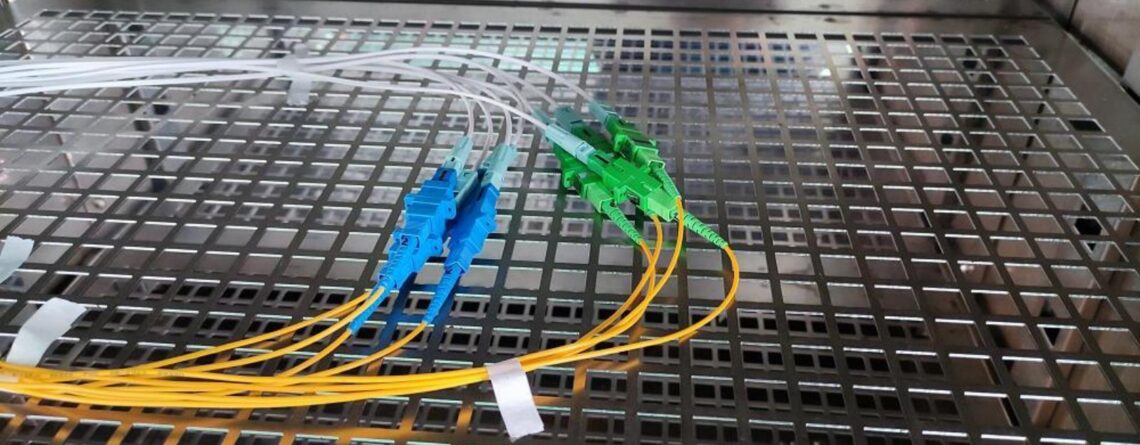

Test Purpose: Ceramic V-Groove field assembly connector is widely used in field fiber connection. Due to the profit driven, there are some cheaper copy type in the market. So how is the copy type perform? Will it meet the data requirements? We did two tests to distinguish how the Ceramic-V Groove copy type and CCTC type works under climate testing. Hope the tests we had this time will give you some information about these questions.

Sample Information:

| Sample Name | Field Assembly Connector | ||

| Sample Mode | FAC-SC/APC&UPC-05 | ||

| Sample Quantity | Test 1 | Test 2 | |

| COPY#1 | COPY#2 | CCTC | |

| 4 APC, 4 UPC | 2 APC, 2UPC | 2 APC, 2UPC | |

| Sample Condition | Good Appearance, good performance with room temperature | ||

| Pic of 3 Ceramic-V Groove | |||

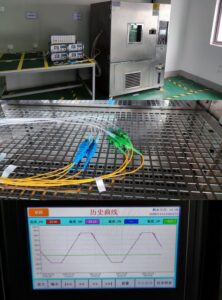

Test Information

| Test Project | High and low temperature cycle test | |

| Test Standard | -25℃-+75℃ | |

| Test Date | Test 1(COPY#1) | Test 2(COPY#2, CCTC) |

| Dec 9th, 2021 | Dec 16th, 2021 | |

| Test Period | 24hrs | 24hrs |

| Test Equipment | Programmable Constant Temperature And Humidity Test Chamber | |

Test Process: Connect products and put in the equipment. Turn on the equipment and set temperature. The test exposes connectors to the high temperature and low temperature of -25℃-+75℃. Routine 24 hours 4 high and low temperature cycles. The rate of heating and cooling is 1 degree Celsius per minute.